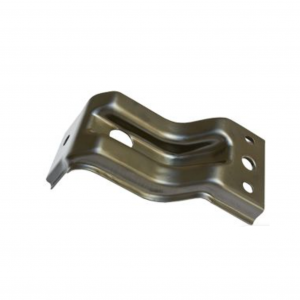

Likarolo tsa tšepe tsa setempe sa aluminium

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe feela | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Likarolo tsa likoloi, likarolo tsa mochini oa temo, likarolo tsa mochini oa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa jarete, likarolo tsa mochini tse sa silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, likarolo tsa lisebelisoa tsa Hardware, likarolo tsa ho bapala, likarolo tsa elektroniki, jj. | |||||||||||

Melemo

1. Ho feta lilemo tse 10ea botsebi ba khoebo ea mose ho maoatle.

2. Fana katšebeletso e le 'ngoeho tloha ho moralo oa hlobo ho isa ho phano ea lihlahisoa.

3. Nako ea ho fana ka potlako, hoo e ka bangMatsatsi a 30-40. E fumaneha ka har'a beke.

4. Tsamaiso e tiileng ea boleng le taolo ea tšebetso (ISOmoetsi le feme ea tiisitsoeng).

5. Litheko tse utloahalang haholoanyane.

6. Setsebi, fektheri ea rona e na leho feta 10lilemo tsa histori tšimong ea tšepe stamping lakane tšepe.

Tsamaiso ea boleng

Sesebelisoa sa thata sa Vickers.

Sesebelisoa sa ho lekanya profaele.

Sesebelisoa sa spectrograph.

Lisebelisoa tse tharo tsa ho hokahanya.

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

Boemo ba Khoebo

E le e mong oa barekisi ba ka sehloohong ba China ba tšepe ea tšepe, Ningbo Xinzhe Metal Products Co., Ltd e tsepamisitse maikutlo ho hlahiseng likarolo tsa koloi, likarolo tsa mochini oa temo, likarolo tsa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa Hardware, likarolo tsa mochini tse silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, lisebelisoa tsa Hardware, lintho tsa ho bapala le lisebelisoa tsa elektroniki, har'a lintho tse ling.

Mahlakore ka bobeli a rua molemo ka bokhoni ba rona ba ho utloisisa 'maraka oo re o lebelletseng le ho fana ka likhothaletso tse sebetsang tse tla thusa bareki ba rona ho fumana karolo e kholo ea mmaraka. Re ikemiseditse ho fa bareki ba rona tshebeletso e tswileng matsoho le dikarolo tsa premium hore ba tle ba re tshepe. Theha likhokahano tse tšoarellang le bareki ba hajoale le ho phehella khoebo e ncha linaheng tseo e seng balekane ho khothaletsa tšebelisano.

Ts'ebetso ea oxidation

Mehato e latelang hangata e kenyelelitsoe ts'ebetsong ea oxidation:

1. Phepelo ea lintho tse tala: Sebelisa liphaephe ho fana ka lisebelisoa tse tala ho reactor e le ho boloka tekano e nepahetseng ea lisebelisoa tse tala ka hare.

2. Boitšoaro: Ho phethahatsa karabelo ea oxidation, eketsa oksijene ho reactor 'me u laole likarolo tsa karabelo (joalo ka mocheso, khatello, le nako ea karabelo).

3. Karohano ea sehlahisoa: Sebelisa moea o pholileng ho hatsetsa sehlahisoa se arabetsoeng, ho se fetola ho tloha sebakeng sa khase ho se etsa mokelikeli kapa se tiileng, ebe u sebelisa searola ho arola lihlahisoa tse tsoang likarolong tse sa tšoaneng.

4. Tlhoekiso: Ho etsa bonnete ba hore sehlahisoa sa karabelo se fihla bohloeki bo hlokahalang, se hloekise.

5. Liphutheloana: Ka mor'a hore lihlahisoa li hloekisoe, li kenngoa ho latela tataiso le litekanyetso pele li rekisoa ho bareki kapa li romelloa mothating o latelang oa ho sebetsa.

Lisebelisoa tse ling tse khethehileng, tse kang semiconductor wafer processing, mokhoa oa oxidation o boetse o kenyelletsa ho fana ka li-oxidants (tse kang metsi, oksijene) le matla a mocheso holim'a silicon substrate ho etsa filimi ea silicon dioxide (SiO2). Filimi ena ea oxide e sireletsa sephaphatha ka ho thibela ho lutla ha hona joale ho phalla pakeng tsa lipotoloho, ho thibela ho hasana nakong ea ts'ebetso ea ho kenngoa ha ion, le ho sebetsa e le filimi e thibelang etching e thibelang etching e fosahetseng nakong ea ts'ebetso ea etching.