Litheolelo tse Tloaelehileng tsa OEM Sheet Metal Stamping Part Precision Stainless Stainless Aluminium Brass Components

Re ipapisitse le matla a matla a tekheniki 'me re tsoela pele ho theha mahlale a tsoetseng pele ho fihlela tlhoko ea Likarolo tse Tloaelehileng tsa Discount Custom OEM Sheet Metal Stamping Precision Stainless Stainless Steel Aluminium Brass Components, Khoebo ea rona e se e ntse e ahile sehlopha se nang le boiphihlelo, boqapi le ba nang le boikarabello ho theha bareki ha ba ntse ba sebelisa molao-motheo oa ho hapa mefuta e mengata.

Re itšetlehile ka matla a matla a tekheniki 'me re lula re theha mahlale a tsoetseng pele ho fihlela tlhoko eaChina Sheet Metal Karolo le Sheet Metal Stamping, Re na le bareki ba tsoang linaheng tse fetang 20 mme botumo ba rona bo 'nile ba amoheloa ke bareki ba rona ba hlomphehang. Ntlafatso e sa feleng le ho loanela ho haella ka 0% ke maano a rona a mabeli a mantlha a boleng. Haeba u hloka eng kapa eng, u se ke oa qeaqea ho ikopanya le rona.

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe feela | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Likarolo tsa likoloi, likarolo tsa mochini oa temo, likarolo tsa mochini oa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa jarete, likarolo tsa mochini tse sa silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, likarolo tsa lisebelisoa tsa Hardware, likarolo tsa ho bapala, likarolo tsa elektroniki, jj. | |||||||||||

Mefuta ea litempe

Re fana ka mekhoa e le 'ngoe le e mengata, e tsoelang pele, e tebileng ea ho hula, fourslide, le mekhoa e meng ea litempe ho netefatsa mokhoa o sebetsang ka ho fetisisa oa ho etsa lihlahisoa tsa hau. Litsebi tsa Xinzhe li ka bapisa projeke ea hau le setempe se nepahetseng ka ho hlahloba mofuta oa hau oa 3D o kentsoeng le litšoantšo tsa tekheniki.

- Progressive Die Stamping e sebelisa li-dies le mehato e mengata ho theha likarolo tse tebileng ho feta tse neng li ka fihlelleha ka lefu le le leng. E boetse e nolofalletsa li-geometri tse ngata ka karolo e 'ngoe ha li ntse li feta har'a mefuta e fapaneng. Mokhoa ona o loketse ka ho fetisisa molumo o phahameng le likarolo tse kholo tse kang tsa indasteri ea likoloi. Transfer die stamping ke ts'ebetso e ts'oanang, ntle le hore "stamping" e tsoelang pele e kenyelletsa "workpiece" e kopantsoeng le tšepe e hulang ts'ebetsong eohle.

- Deep Draw Stamping e theha litempe tse nang le likheo tse tebileng, joalo ka likhutlo tse koetsoeng. Ts'ebetso ena e etsa likotoana tse thata ho tloha ha ts'ebetso e feteletseng ea tšepe e hatella sebopeho sa eona hore e be sebopeho sa kristale haholoanyane. Setempe se tloaelehileng sa ho hula, se kenyelletsang likarolo tse sa tebang tse sebelisoang ho bopa tšepe, le tsona li sebelisoa hangata.

- Fourslide Stamping e bopa dikarolo ho tloha ka dilepe tse nne ho fapana le ho tloha nqa e le nngwe. Mokhoa ona o sebelisoa ho etsa likaroloana tse nyane tse rarahaneng tse kenyelletsang likarolo tsa elektronike joalo ka likhokahanyo tsa betri ea mohala.

- Hydroforming ke phetoho ea setempe. Lipampiri li behoa holim'a pola e nang le sebopeho se ka tlase, ha sebopeho se ka holimo ke senya sa oli se tletseng khatello e phahameng, se hatella tšepe ka sebōpeho sa lefu le tlaase.

- Ho koala likotoana ho tloha lakane e le mohato oa pele pele o etsoa. Fineblanking, phapang ea ho koala, e etsa maqeba a nepahetseng a nang le likarolo tse boreleli le bokaholimo bo bataletseng.

- Coining ke mofuta o mong oa sekheo o etsang li-workpieces tse nyane tse chitja. Kaha ho kenyelletsa matla a maholo ho etsa sekotoana se senyenyane, se thatafatsa tšepe 'me se tlosa metsu le mapheo a makukuno.

- Ho otla ka litebele ho fapane le ho koala letho; e kenyelletsa ho tlosa thepa ho tloha ho workpiece ho e-na le ho tlosa thepa ho etsa workpiece.

- Embossing e etsa moralo oa likarolo tse tharo ka tšepe, ebang e phahame ka holim'a metsi kapa ka letoto la ho tepella maikutlo.

- Ho kobeha ho etsahala ka lehlakoreng le le leng 'me hangata ho sebelisoa ho theha li-profile ka libopeho tsa U, V, kapa L. Mokhoa ona o finyelloa ka ho tlanya lehlakore le leng le ho kobeha le leng holim'a thae kapa ho hatella tšepe ho kena kapa ho e thibela.

Tsamaiso ea boleng

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

Mokhoa oa ho hatakela

Metal stamping ke ts'ebetso ea tlhahiso eo ho eona likhoele kapa maqephe a bataletseng a entsoeng ka libopeho tse ikhethileng. Ho hatakela ho kenyelletsa mekhoa e mengata ea ho theha joalo ka ho koala letho, ho otla ka litebele, ho hatisa le ho hatisa ka mokhoa o tsoelang pele, ho bolela tse seng kae feela. Likarolo li sebelisa motsoako oa mekhoa ena kapa ka boikemelo, ho latela ho rarahana ha sengoathoana. Ts'ebetsong, li-coil tse se nang letho kapa lishiti li kenngoa mochineng oa khatiso o sebelisang lisebelisoa le ho shoa ho etsa likarolo le bokaholimo ba tšepe. Metal stamping ke tsela e babatsehang ea ho hlahisa likarolo tse fapa-fapaneng tse rarahaneng ka bongata, ho tloha ho liphanele tsa mamati a koloi le likere ho ea ho lisebelisoa tse nyenyane tsa motlakase tse sebelisoang mehalang le lik'homphieutha. Mekhoa ea litempe e amohetsoe haholo indastering ea likoloi, indasteri, mabone, bongaka le tse ling.

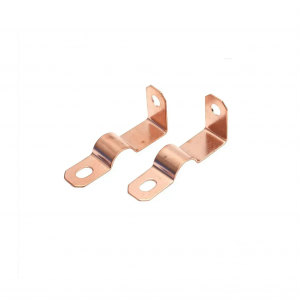

Copper Metal Stamping

Mofani oa litempe tsa tšepe tsa boleng bo holimo ka lilemo tse fetang 10, Xinzhe Metal Stampings e sebelisana le liindasteri tse fapaneng ho fihlela lipheo tsa bona tse thata ka ho fetisisa tsa tekanyetso le ts'ebetso. Re motlotlo ho sebeletsa liindasteri tse latelang:

lisebelisoa tsa elektronike

sefofane

tsa bongaka

lisebelisoa tse khabisitsoeng

kaho

Re fana ka litharollo tse ncha ho liqholotso tsa hau tse kholo ka ho fetesisa tsa koporo.

Li-alloys tsa koporo le tsa koporo li loketse hantle bakeng sa lits'ebetso tsa setempe ka lebaka la ho hanyetsa ha tsona ho kutu, ho ba le li-ductility tse phahameng le moralo o theko e boima. Hangata e sebelisoa bakeng sa lisebelisoa tsa motlakase le tsa mocheso, koporo e na le qetello e khahlehang ea patina e khahlang le likarolo tsa bareki.

Re ipapisitse le matla a matla a tekheniki 'me re tsoela pele ho theha mahlale a tsoetseng pele ho fihlela tlhoko ea Likarolo tse Tloaelehileng tsa Discount Custom OEM Sheet Metal Stamping Precision Stainless Stainless Steel Aluminium Brass Components, Khoebo ea rona e se e ntse e ahile sehlopha se nang le boiphihlelo, boqapi le ba nang le boikarabello ho theha bareki ha ba ntse ba sebelisa molao-motheo oa ho hapa mefuta e mengata.

Tloaelehileng TheoleloChina Sheet Metal Karolo le Sheet Metal Stamping, Re na le bareki ba tsoang linaheng tse fetang 20 mme botumo ba rona bo 'nile ba amoheloa ke bareki ba rona ba hlomphehang. Ntlafatso e sa feleng le ho loanela ho haella ka 0% ke maano a rona a mabeli a mantlha a boleng. Haeba u hloka eng kapa eng, u se ke oa qeaqea ho ikopanya le rona.