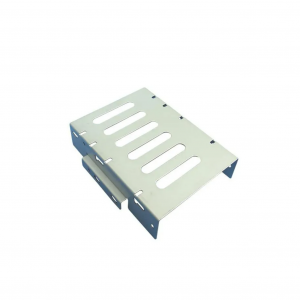

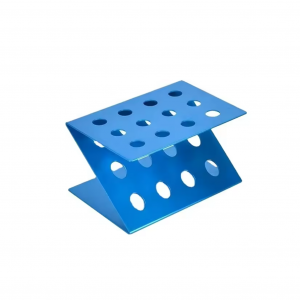

OEM Laser Cut le Bent Sheet Metal Stainless Steel Bracket

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe feela | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Likarolo tsa likoloi, likarolo tsa mochini oa temo, likarolo tsa mochini oa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa jarete, likarolo tsa mochini tse sa silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, likarolo tsa lisebelisoa tsa Hardware, likarolo tsa ho bapala, likarolo tsa elektroniki, jj. | |||||||||||

Tiisetso ea boleng

tsamaiso e thata ea ho laola boleng

Ho etsa bonnete ba hore mohato o mong le o mong oa ts'ebetso-ho tloha ho fumana thepa e tala ho ea ho lihlahisoa tsa lihlahisoa-e kopana le litlhoko tsa boleng tse reriloeng esale pele, re kentse tsamaiso e pharaletseng ea tsamaiso ea boleng. Re fumane tumello bakeng sa litsamaiso tsa boleng ba ISO 9001:2015 le ISO 9001:2000, tse khomarelangISO 9001leISO 9001:2000Litlhoko tsa tsamaiso ea boleng, 'me li lula li ntlafatsa khotsofalo ea bareki le boleng ba sehlahisoa ka ho ntlafatsa ts'ebetso.

khetho e phahameng ea lisebelisoa tsa motheo

Kaha re tseba hantle hore boleng ba lihlahisoa tse tala bo ama ka ho toba boleng ba sehlahisoa se felileng, re khetha ka hloko bafani ba rona ho etsa bonnete ba hore thepa e tala eo re e rekang e latela melao le litekanyetso tsohle tse sebetsang. E le ho netefatsa phepelo e tsitsitseng ea thepa e tala le boleng bo laolehang, re theha litumellano tsa tšebelisano ea nako e telele le bafani ba thepa ba tšepahalang.

Tsamaiso ea boleng

Sesebelisoa sa thata sa Vickers.

Sesebelisoa sa ho lekanya profaele.

Sesebelisoa sa spectrograph.

Lisebelisoa tse tharo tsa ho hokahanya.

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

Ho itšeha ka laser

Ho itšeha ka laser ho tumme haholo indastering ea ts'ebetso ea lakane ka lebaka la boemo ba eona bo phahameng ba ho feto-fetoha ha maemo, bokhoni ba ho itšeha bo potlakileng le bo sebetsang, le potoloho e khuts'oane ea ho sebetsa ha sehlahisoa. Litšobotsi tsena li etsa hore laser e be khetho e nepahetseng bakeng sa ho etsa likarolo tse nepahetseng.

Ho itšeha ka laser ho sebelisa lebone la laser ea matla a phahameng ho sebetsana le lisebelisoa tsa tšepe. E na le melemo ea ho nepahala ho phahameng, lebelo le phahameng, le ho se kopane. E sebelisoa haholo indastering ea ho etsa le ho lokisa ea mochini joalo ka likhabinete tsa chassis, lisebelisoa tsa lapeng, lisebelisoa tsa kichineng, mabone, lihlahisoa tsa elektroniki le tsa motlakase, lihlahisoa tsa Hardware, lisebelisoa le limithara, metjhini e nepahetseng, meaho ea tšepe le tlhahiso ea lifti.

LBH

1.Q: Mokhoa oa ho lefa ke ofe?

A: Re amohela TT (Bank Transfer), L/C.

(1. Bakeng sa kakaretso ea chelete e ka tlase ho US$3000, 100% esale pele.)

(2. Bakeng sa kakaretso ea chelete e ka holimo ho US$3000, 30% esale pele, e setseng khahlanong le tokomane ea kopi.)

2.Q: Feme ea hau e hokae?

A: Feme ea rona e Ningbo, Zhejiang.

3.Q: Na u fana ka mehlala ea mahala?

A: Hangata ha re fane ka mehlala ea mahala. Ho na le mohlala oa litšenyehelo tse ka khutlisetsoang ka mor'a hore u behe odara.

4.Q: U atisa ho romela eng?

A: Thepa ea lifofane, thepa ea leoatleng, e hlalosang ke eona tsela e molemohali ea ho romelloa ka lebaka la boima bo nyane le boholo ba lihlahisoa tse nepahetseng.

5.Q: Ha ke na setšoantšo kapa setšoantšo se fumanehang bakeng sa lihlahisoa tse tloaelehileng, na u ka se qapa?

A: Ee, re ka etsa moralo o nepahetseng ka ho fetesisa ho latela kopo ea hau.