Elevator leveling bataletseng ho kopana switjha tšepe sekotoana

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe feela | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Lisebelisoa tsa lifti, lisebelisoa tsa mochini oa boenjiniere, lisebelisoa tsa boenjiniere ba kaho, lisebelisoa tsa likoloi, lisebelisoa tsa mochini oa ts'ireletso ea tikoloho, lisebelisoa tsa likepe, lisebelisoa tsa sefofane, lisebelisoa tsa liphaephe, lisebelisoa tsa lisebelisoa tsa Hardware, lisebelisoa tsa ho bapala, lisebelisoa tsa elektroniki, jj. | |||||||||||

Melemo

1. Ho feta10 lilemoea botsebi ba khoebo ea mose ho maoatle.

2. Fana katšebeletso e le 'ngoeho tloha ho moralo oa hlobo ho isa ho phano ea lihlahisoa.

3. Nako ea ho fana ka potlako, matsatsi a ka bang 25-40.

4. Tsamaiso e tiileng ea boleng le taolo ea tšebetso (ISO 9001moetsi le feme ea tiisitsoeng).

5. Phepelo e tobileng ea fektheri, theko ea tlhōlisano.

6. Setsebi, fektheri ea rona e sebeletsa indasteri ea ts'ebetso ea tšepe 'me e sebelisitselaser ho itšehatheknoloji ho feta10 lilemo.

Tsamaiso ea boleng

Sesebelisoa sa thata sa Vickers.

Sesebelisoa sa ho lekanya profaele.

Sesebelisoa sa spectrograph.

Lisebelisoa tse tharo tsa ho hokahanya.

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

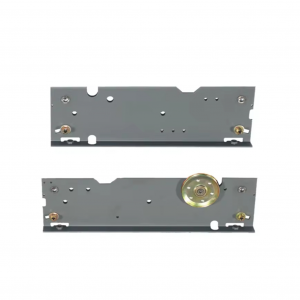

Leqephe la ho ikopanya le switjha ke eng?

Letlapa la ho ikopanya le tšepe la sesebelisoa sa ho ikopanya le sephara ke karolo ea bohlokoa kopanong ea switjha. Hangata e sebelisoa tsamaisong ea puisano ea lisebelisoa tsa motlakase le tsa elektroniki.

Mosebetsi le karolo

Mosebetsi oa conductive: Letlapa la ho ikopanya le tšepe ea switjha le sebetsa e le mokhanni oa potoloho. E le ho koala ka ho feletseng kapa ho khaola potoloho, hona joale e fetisoa ka letlapa la ho kopana ho tloha ho electrode e 'ngoe ho ea ho e' ngoe ha sesebelisoa se hatelloa.

Matla a ho hlaphoheloa a elastic: Hangata ho na le elasticity letlapeng la tšepe. E tla hlokomela ho buloa le ho koaloa khafetsa ha switch ka ho holofala ha e hatelloa le ho khutlela maemong a eona a tloaelehileng ha e lokolloa.

Ts'ebetso e tšepahalang ea ho ikopanya: Ka ho theola khanyetso ea ho ikopanya le ho fana ka khatello e tsitsitseng ea ho ikopanya, letlapa la ho ikopanya le tšepe le ka tiisa ts'ebetso e ntle ea ho kopana le motlakase nakong eohle ea ho hatella le ho lokolla.

Khetho ea lintho tse bonahalang

Lisebelisoa tse tloaelehileng: Lisebelisoa tsa letlapa la tšepe tse atisang ho sebelisoa li-switches tse bataletseng li kenyelletsa tšepe e sa hloekang, alloy ea koporo, alloy ea nickel le tšepe e entsoeng ka silevera. Khetho ea lisebelisoa tse fapaneng e itšetlehile ka tikoloho ea tšebeliso le litlhoko tsa ts'ebetso.

Ts'epe e sa beng le mabali: E na le khanyetso e ntle ea kutu le elasticity mme hangata e sebelisoa li-switches libakeng tse thata.

Motsoako oa koporo: E na le conductivity e ntle haholo 'me hangata e sebelisoa liketsahalong tse hlokang conductivity e phahameng.

Likotoana tse amanang le silevera kapa khauta: Likarolo tsa ho ikopanya tse nang le litšepe tsa bohlokoa holim'a metsi li na le conductive haholoanyane 'me li ka thibela oxidation ka katleho, li lelefatsa bophelo ba tšebeletso.

Sebopeho le sebopeho

Moqapi o bataletseng: Bakeng sa ho sebelisoa lits'ebetsong tse nyane, likarolo tsa ho ikopanya tse bataletseng hangata li entsoe ka thepa e tšesaane, e bataletseng. Moralo ona o loketse lisebelisoa tsa elektroniki tse hlokang ho boloka sebaka hobane o ka tšesaane ka kakaretso.

Moqapi oa bump: Ho netefatsa sebaka se senyenyane sa ho kopana ha o kopana, likarolo tse ling tsa ho ikopanya li entsoe ka makukuno a manyane holim'a tsona. Sena se theola khanyetso ea ho ikopanya le ho eketsa ts'epo ea ho ikopanya.

Ho hatakela: Mokhoa oa ho hatakela likotoana tsa tšepe tse amanang le tšepe o fana ka boholo bo nepahetseng haholo le sebopeho hammoho le matla a itseng a ho hlaphoheloa.

Litšebeletso tsa Rōna

Xinzhe Metal Products Co., Ltd. ke moetsi ea ka sehloohong oa lesela la tšepe naheng ea China.

Ho itšeha ka laser, ho seha terata, ho hatakela, ho kobeha, le ho tjheseletsake mekhoa ea mantlha ea ts'ebetso.

Theknoloji ea mantlha e sebelisoang kalafong ea holimo keho qhomisa lehlabathe, electrophoresis, electroplating, anodizing, le ho fafatsa.

Lihlahisoa tse ka sehloohong li kenyelletsa lihokelo tsa sebopeho sa tšepe, li-brackets tsa seismic, li-brackets tsa lerako,masakana a tsitsitseng, masakana a hokelang, masakaneng a kholomo, liporo tsa tataiso ea lifti,masakaneng seporo se tataisang, masakaneng a koloi, masakaneng a boima ba 'mele, masakaneng a lisebelisoa tsa kamore ea mochini, masakaneng a sistimi ea mamati, masakaneng, litšepe tsa terene ea lifti,tataiso ea seporo lipoleiti tse kopanyang, liboutu le linate, liboutu tsa katoloso, li-washer tsa selemo, li-washer tse bataletseng, li-washer tse notlellang, li-rivets, lithakhisa le lisebelisoa tse ling tsa moaho. Re fana ka lisebelisoa tse ikhethileng bakeng sa mefuta e fapaneng ea lifti bakeng sa lihlahisoa tsa lefats'e joalo kaSchindler, Kone, Otis, ThyssenKrupp, Hitachi, Toshiba, Fujita, Conley, Doverle ba bang.