Likarolo tse entsoeng ka mokhoa o nepahetseng oa tšepe le likarolo tse kobehang

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe feela | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Likarolo tsa likoloi, likarolo tsa mochini oa temo, likarolo tsa mochini oa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa jarete, likarolo tsa mochini tse sa silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, likarolo tsa lisebelisoa tsa Hardware, likarolo tsa ho bapala, likarolo tsa elektroniki, jj. | |||||||||||

Tiisetso ea boleng

1. Lihlahisoa tsohle tsa tlhahiso le tlhahlobo li na le litlaleho tsa boleng le lintlha tsa tlhahlobo.

2. Likarolo tsohle tse lokiselitsoeng li etsa liteko tse thata pele li romelloa ho bareki ba rona.

3. Haeba e 'ngoe ea likarolo tsena e senyehile tlas'a maemo a tloaelehileng a ho sebetsa, re tšepisa ho e nkela sebaka ka bonngoe mahala.

Ke kahoo re ts'epang hore karolo efe kapa efe eo re fanang ka eona e tla etsa mosebetsi mme e tle le waranti ea bophelo bohle khahlanong le likoli.

Tsamaiso ea boleng

Sesebelisoa sa thata sa Vickers.

Sesebelisoa sa ho lekanya profaele.

Sesebelisoa sa spectrograph.

Lisebelisoa tse tharo tsa ho hokahanya.

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

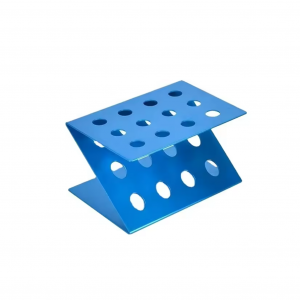

Mefuta ea likarolo tse kobehang

Mefuta e tloaelehileng ea likarolo tse kobehang tsa sheet metal:

1. Lisebelisoa tsa mabokose: Likhabinete, chassis, mabokose a lisebelisoa, mabokose a motlakase, le lisebelisoa tse ling tse tšoanang ke tsona tse atileng haholo ts'ebetsong ea litšepe. Lisebelisoa tse bataletseng li ka kobelloa ka har'a likarolo tse fapaneng tsa lebokose li sebelisa ho kobeha ka tšepe ea sheet, ebe li ka kopanngoa kapa tsa chesetsoa hammoho ho etsa lebokose lohle.

2. Li-bracket workpieces: Lisebelisoa tsena tsa mosebetsi, tse kenyelletsang li-brackets tsa foreimi e bobebe le li-brackets tse boima tsa mechine, hangata li entsoe ka lipoleiti tsa tšepe ka bolelele le bophara bo fapaneng. Li-brackets tse nang le litlhaloso tse fapaneng li ka hlahisoa ho sebelisoa ho kobeha ha tšepe ea sheet ka ho fetola sekhutlo le bolelele ba ho kobeha.

3. Li-workpieces tse chitja: Lisebelisoa tsena haholo-holo li na le likarolo tse chitja le tse kholo, har'a tse ling. Semicircular e sephara, e bōpehileng joaloka lekala, le lisebelisoa tse ling li ka kobeha likarolong tse chitja ka ho sebelisa theknoloji ea ho kobeha ea tšepe. Ka ho laola ka nepo sekhutlo se kobehang, tlhahiso ea likarolo tse chitja e nepahetseng haholo e ka finyelloa.

Li-workpieces tsa 4.Bridge: bolelele ba li-workpieces tsena le li-angles tse kobehang li fapana ho latela mofuta oa ts'ebeliso, joalo ka litepisi tsa mabone a sethala, lisebelisoa tsa boikhathollo, joalo-joalo. Lisebelisoa tse kang borokho ka boholo bo fapaneng li ka hlahisoa ka thekenoloji ea ho kobeha ea tšepe ea lakane, 'me li na le melemo ea boemo bo nepahetseng, ho nepahala ha ts'ebetso e phahameng, le ho hlongoa habonolo.

5. Mefuta e meng ea li-workpiece: Ho na le mefuta e sa tšoaneng ea li-workpiece, tse kenyelletsang mehaho ea tšepe, marulelo, likhetla, le tse ling, ho phaella ho li-workpieces tse tloaelehileng tsa ho kobeha tsa tšepe tse boletsoeng pejana. Mekhoa ea profeshenale ea tšepe e kobehang ea longitudinal le transverse process ea hlokahala bakeng sa mefuta e fapaneng ea workpiece.

Hobaneng o re khetha

1.Setsebi se entsoeng ka lesela la tšepe le likarolo tsa setempe sa tšepe ka nako e fetang lilemo tse leshome.

2. Boemo bo phahameng ba tlhahiso ke ntho eo re tsepamisang maikutlo ho eona haholoanyane.

3. Ts'ehetso e ikhethang e fumanehang bosiu le motšehare.

4. Nakong ea khoeli, ho pepa ho etsahala kapele.

5. Sehlopha se matla sa tekheniki se tšehetsang le ho tšehetsa lipatlisiso le nts'etsopele.

6. Hlahisa tšebelisano ea OEM.

Re fumana maikutlo a matle ho tsoa ho bareki ba rona le litletlebo tse fokolang haholo.

8. Sehlahisoa se seng le se seng se na le thepa e ntle ea mochini le nako e ntle ea bophelo.

9. Theko ea tlhōlisano e loketseng.