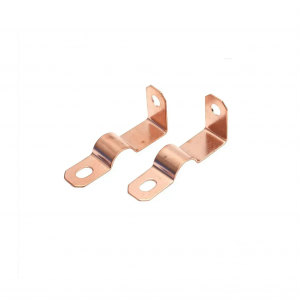

Bracket e Tloaelehileng e koahetsoeng ke Elevator e Otlolohileng ea Angle Bracket

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe feela | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Likarolo tsa likoloi, likarolo tsa mochini oa temo, likarolo tsa mochini oa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa jarete, likarolo tsa mochini tse sa silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, likarolo tsa lisebelisoa tsa Hardware, likarolo tsa ho bapala, likarolo tsa elektroniki, jj. | |||||||||||

Melemo

1. Ho feta lilemo tse 10 ea botsebi ba khoebo ea mose ho maoatle.

2. Fana katšebeletso e le 'ngoe ho tloha ho moralo oa hlobo ho isa ho phano ea lihlahisoa.

3. Nako ea ho fana ka potlako, hoo e ka bangMatsatsi a 30-40.

4. Tsamaiso e tiileng ea boleng le taolo ea tšebetso (ISO moetsi le feme ea tiisitsoeng).

5. Phepelo e tobileng ea fektheri, theko ea tlhōlisano.

6. Setsebi, fektheri ea rona e sebelelitse indasteri ea ho sebetsa ka lakane 'me e sebelisitse ho itšeha ka laser ho feta10 lilemo.

Tsamaiso ea boleng

Sesebelisoa sa thata sa Vickers.

Sesebelisoa sa ho lekanya profaele.

Sesebelisoa sa spectrograph.

Lisebelisoa tse tharo tsa ho hokahanya.

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

Ho roala ka phofo

Powder coating ke thekenoloji ya kalafi ya bokahodimo e fafatsang pente e phofshwana ka ho lekana hodima tshepe ka ho fafatsa ka electrostatic, ebe e qhibidiha le ho tiisa phofo ka ho futhumala ho etsa lesela le matla le le tshwarellang.

Melemo ea mantlha ea ho roala phofo:

Tšireletso ea tikoloho- Ha ho na mesi e hlahisoang ke "volatile organic compound" (VOC), e nang le botsoalle ho tikoloho.

Ho tšoarella- Ho hanyetsa kutu e ntle haholo le ho hanyetsa ho roala.

Aesthetics- E fumaneha ka mefuta e fapaneng ea mebala le litlamorao tsa bokaholimo (joalo ka gloss, matte, sebopeho).

Katleho ea litšenyehelo- Tšebeliso e phahameng ea pente le mokhoa o sebetsang oa ho roala.

Ho roala ka phofo ho sebelisoa haholo kalafong ea holim'a lihlahisoa tse fapaneng tsa tšepe, haholo-holo ho kenyelletsa le masimo a latelang:

Mehaho le mokhabiso

Liforeimi tsa mamati le lifensetere

Balebeli le litšepe

Mehaho ea ho haha

Likarolo tsa mokhabiso oa ka hare

Indasteri ea likoloi

Likarolo tsa 'mele

Likarolo tsa chassis

Likarolo tse ka hare

Likarolo tsa enjene le tsa mochini

Indastering ea lifti, ho roala ha phofo ho sebelisoa haholo kalafong ea bokaholimo ba likarolo tse fapaneng tsa lifti ka lebaka la ho hanyetsa ha eona ho hoholo ha kutu, ho hanyetsa ho roala le botle bo botle.

Mehlala ea ts'ebeliso:

Liphanele tsa mamati a lifti le liforeimi

Ho roala ha phofo ha ho ntlafatse feela ho hanyetsa ha kutu, empa hape ho fana ka mebala e sa tšoaneng le mekhoa e metle ho ntlafatsa ponahalo le moralo oa lifti.

Litšepe tsa tataiso ea liftile batataisi

E fana ka lubricity e ntle le khanyetso ea ho roala likarolong tsena ho netefatsa ts'ebetso e bonolo ea lifti.

Likamore tsa likoloi tsa lifti li kenyelletsa siding ea koloi, siling lelifensetere tsa lifti

Ka phekolo ea ho roala phofo, ha se feela phello e khabisitsoeng e ntlafatsoang, empa le ho tšoarella hoa ntlafatsoa.

Liphanele tsa konopo ea liftile lik'habote tsa taolo

Ho roala ha phofo ho fana ka sebaka se thibelang likokoana-hloko le se sa senyeheng bakeng sa likarolo tsena tse atisang ho kopana, ho netefatsa tšebeliso ea nako e telele.

Tšebeliso ea theknoloji ea ho roala phofo indastering ea lifti e ntlafalitse haholo ts'ebetso le ponahalo ea lisebelisoa tsa lifti, ha e ntse e fokotsa litšenyehelo tsa tlhokomelo le bophelo bo ntseng bo eketseha ba ts'ebeletso.

LBH

P: Na u k'hamphani ea khoebo kapa moetsi?

A: Re tengmoetsi.

P: Joang ho fumana quote?

A: Ka kopo, romella litšoantšo tsa hau (PDF, stp, igs, step ...) ho rona ka imeile , 'me u re bolelle thepa, phekolo ea holim'a metsi le bongata, ebe re tla u etsetsa quotation.

P: A na nka odara karolo e le 'ngoe kapa tse peli bakeng sa tlhahlobo feela?

A: Ntle ho pelaelo.

Q: A na u ka etsa ho latela lisampole?

A: Re khona ho hlahisa ho latela mehlala ea hau.

P: Nako ea ho fana ka nako e kae?

A: Ho itšetlehile ka boholo ba taelo le boemo ba sehlahisoa, matsatsi a 7 ho isa ho a 15.

P: Na u hlahloba ntho e 'ngoe le e' ngoe pele u e romela?

A: Pele re romelloa, re etsa tlhahlobo ea 100%.

P: U ka theha likamano tse tiileng tsa nako e telele tsa khoebo joang?

A:1. Ho netefatsa melemo ea bareki ba rona, re boloka maemo a holimo a boleng le theko ea tlholisano;

2. Re tšoara moreki e mong le e mong ka setsoalle le khoebo e fetisisang, ho sa tsotellehe hore na o tsoa hokae.