Likarolo tsa ho taka tse tebileng tsa tšepe

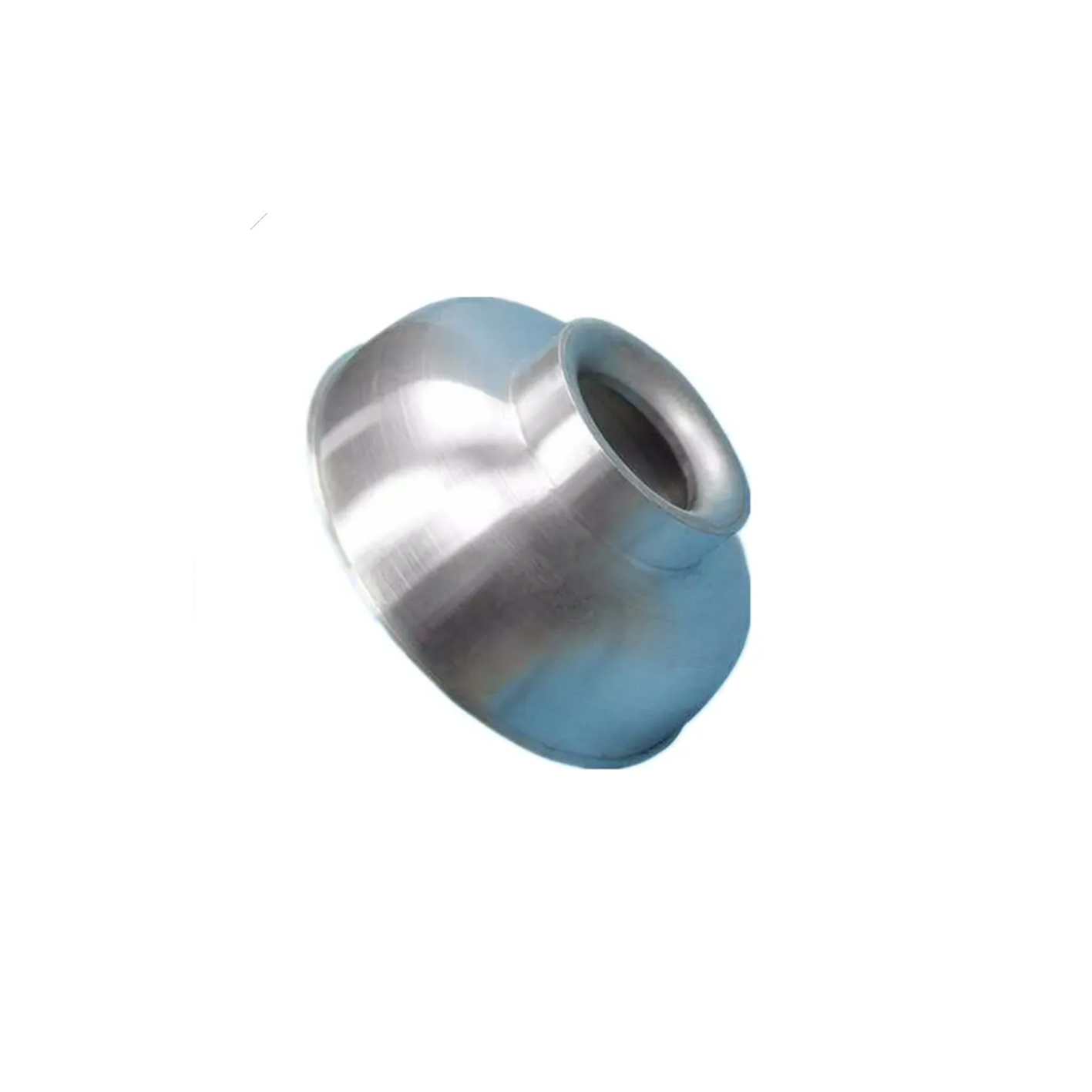

Ka nts'etsopele ea sechaba, likarolo tsa litempe li entsoe liindasteri tse fapaneng, 'me likarolo tsa setempe li ka bonoa hohle bophelong ba letsatsi le letsatsi. Ho na le mefuta e mengata ea likotoana tsa mosebetsi oa setempe, tse sebelisoang likarolong tsohle tsa bophelo, lelikarolo tsa tšepe tse tebileng tsa ho taka ke e 'ngoe ea tsona. Tšepemothalo o tebilengho hatakelake ho sebelisa mochini oa setempe ho holofatsa lisebelisoa tsa tšepe tse bōpehileng joaloka poleiti hore e be cylindrical, rectangular, trapezoidal, spherical and conical parts ka ho sebelisa mokhoa oa ho hula mehele kapa hlobo ea tšepe. Haeba li kopantsoe le mekhoa e meng ea setempe, likarolo tse rarahaneng le tse nepahetseng le tsona li ka hlahisoa. Ka kakaretso, ductility ea tšepe e tla ama ka ho toba katleho ea tlhahiso le boleng ba setšoantšo se tebileng, kahoo li-flakes tsa tšepe li atisa ho sebelisoa e le lisebelisoa tse tala bakeng sa ho hatakela. The tebile hulangkarolosts'ebetso ke mokhoa o khahlisang haholo oa ho theha hobane o boloka lisebelisoa. Lisebelisoa tse tloaelehileng tsa tensile li kenyelletsa alloy ea aluminium, tšepe, zinki, koporo le lisebelisoa tse ling.-

Customized ho nepahala huleloa likarolo tšepe sebetsa phepelo

-

Custom Sheet Metal Steel Aluminium le Copper Stamping Components

-

Customized Heavy Carbon Steel Sheet Metal Stamping Deep Drwn Parts

-

Letlapa la 'mele la Custom Stamping Lamp bakeng sa fektheri ea Ceiling Lighting

-

Likoahelo tsa aluminium tse ikhethileng bakeng sa linkho tse fapaneng tsa polokelo le likoahelo tsa botlolo ea tšepe

-

Likarolo tse Tloaelehileng tsa Metal Stamping Sets'oants'o se Tebileng sa Leqephe la Ts'epe

-

OEM tloaelo lakane tšepe setempe likarolo lakane tšepe stamping likarolo

-

OEM Metal carbon steel Deep Drawn Pressing Components Ka theko ea tlholisano

-

Custom Sheet Metal Fabrication Steel Pipe End Caps

-

Likarolo tsa likoloi tse sirelelitsoeng ka mocheso o phahameng tse huleloang ka botebo

-

moetsi customized tšepe e sa jeleng paate Sheet Metal deep drawing Parts

-

OEM ODM tšepe ea boleng bo holimo e hatakela karolo ea tšepe e tebileng ea ho taka