Likarolo tse kholo tsa Kaho ea Elevator Basebeletsi ba Kaho le Likarolo tsa Lilifi tsa Thepa

Re tla ikitlaelletsa ho fa bareki ba rona ba hlomphuoang re sebelisa lits'ebeletso tse nahannoeng ka tjantjello bakeng sa Basebetsi ba Kaho ea Liphoofolo tse kholo tsa Kaho ea Elevator le Li-Wire Rope Connectors, Hammoho le boikitlaetso ba rona, lihlahisoa tsa rona le tharollo li hapile ts'epo ea bareki mme li ka rekisoa haholo mona le kantle ho naha.

Re tla ikitlaelletsa ho fa bareki ba rona ba hlomphuoang re sebelisa litšebeletso tse nahannoeng ka ho fetisisa bakeng saLisebelisoa tsa Kaho ea Chaena le Lisebelisoa tsa Kaho, Moralo, ts'ebetso, ho reka, ho hlahloba, ho boloka, ho bokella, kaofela li ts'ebetsong ea mahlale le e sebetsang ea litokomane, ho eketsa boemo ba ts'ebeliso le ts'epahalo ea mofuta oa rona ka botebo, e leng se etsang hore re be morekisi ea phahameng oa lihlopha tse 'ne tse kholo tsa lihlahisoa tsa likhetla ka har'a naha mme re fumane ts'epo ea moreki hantle.

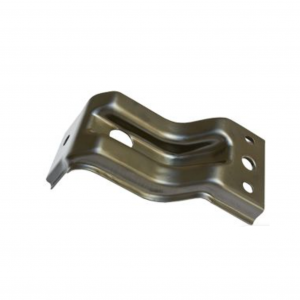

Tlhaloso

| Mofuta oa Sehlahisoa | sehlahisoa se ikhethileng | |||||||||||

| Tšebeletso e le 'ngoe | Ntlafatso ea hlobo le moralo-romela lisampole-batch tlhahiso-hlahloba-ka holim'a kalafo-packaging-phepelo. | |||||||||||

| Tshebetso | ho hatakela, ho kobeha, ho taka ka botebo, ho etsoa ha tšepe ea pampiri, ho cheselletsa, ho itšeha ka laser jj. | |||||||||||

| Lisebelisoa | carbon tšepe, tšepe e sa hloekang, aluminium, koporo, tšepe ea masenke joalo-joalo. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Likarolo tsa likoloi, likarolo tsa mochini oa temo, likarolo tsa mochini oa boenjiniere, likarolo tsa boenjiniere ba kaho, lisebelisoa tsa jarete, likarolo tsa mochini tse sa silafatsang tikoloho, likarolo tsa sekepe, likarolo tsa sefofane, lisebelisoa tsa liphaephe, likarolo tsa lisebelisoa tsa Hardware, likarolo tsa ho bapala, likarolo tsa elektroniki, jj. | |||||||||||

Indasteri Metal Stampings Solutions

Xinzhe Metal Stampings e na le boiphihlelo bo pharalletseng ba ho theha likarolo tsa setempe sa tloaelo li sebelisa litharollo tsa tšepe tse batang bakeng sa liindasteri tse ngata. Tse ling tsa lihlahisoa tse tloaelehileng tsa litempe tsa tšepe li kenyelletsa: ho etsa libara tsa libese, li-flanges, li-escutcheon, li-fasteners, likhokahano tsa betri, matlo a motlakase, likotoana, li-washer le lihlahisoa tse ling tse fapaneng. Re motlotlo ho sebeletsa liindasteri tse fapaneng tse kang Areospace, Medical, Construction, Automotive, Electrionics, Marine, le Lighiting.

Tsamaiso ea boleng

Setšoantšo sa Thomello

Mokhoa oa Tlhahiso

01. Moqapi oa hlobo

02. Mold Processing

03. Ts'ebetso ea ho itšeha ka terata

04. Phekolo ea mocheso oa hlobo

05. Kopano ea hlobo

06. Ho lokisa hlobo

07. Deburring

08. electroplating

09. Teko ea Lihlahisoa

10. Sephutheloana

Mokhoa oa ho hatakela

Metal stamping ke ts'ebetso ea tlhahiso eo ho eona likhoele kapa maqephe a bataletseng a entsoeng ka libopeho tse ikhethileng. Ho hatakela ho kenyelletsa mekhoa e mengata ea ho theha joalo ka ho koala letho, ho otla ka litebele, ho hatisa le ho hatisa ka mokhoa o tsoelang pele, ho bolela tse seng kae feela. Likarolo li sebelisa motsoako oa mekhoa ena kapa ka boikemelo, ho latela ho rarahana ha sengoathoana. Ts'ebetsong, li-coil tse se nang letho kapa lishiti li kenngoa mochineng oa khatiso o sebelisang lisebelisoa le ho shoa ho etsa likarolo le bokaholimo ba tšepe. Metal stamping ke tsela e babatsehang ea ho hlahisa likarolo tse fapa-fapaneng tse rarahaneng ka bongata, ho tloha ho liphanele tsa mamati a koloi le likere ho ea ho lisebelisoa tse nyenyane tsa motlakase tse sebelisoang mehalang le lik'homphieutha. Mekhoa ea litempe e amohetsoe haholo indastering ea likoloi, indasteri, mabone, bongaka le tse ling.

Ke hobane'ng ha u khetha Xinzhe bakeng sa likarolo tsa tšepe tse tloaelehileng tsa setempe?

Ha u fihla Xinzhe, u tla ho setsebi sa setempe sa tšepe. Re tsepamisitse maikutlo ho setempe sa tšepe ka lilemo tse fetang 10, re sebeletsa bareki ba tsoang lefats'eng lohle. Baenjineri ba rona ba meralo ba nang le litsebo tse phahameng le litsebi tsa hlobo li hloahloa ebile li inehetse.

Sephiri sa katleho ea rona ke sefe? Karabo ke mantsoe a mabeli: litlhaloso le tiisetso ea boleng. Morero o mong le o mong o ikhethile ho rona. Pono ea hau ea e matlafatsa, 'me ke boikarabello ba rona ho etsa hore pono eo e be ea sebele. Re etsa sena ka ho leka ho utloisisa lintlha tsohle tse nyane tsa projeke ea hau.

Ha re tseba mohopolo oa hau, re tla sebeletsa ho o hlahisa. Ho na le li-checkpoints tse ngata nakong eohle ea ts'ebetso. Sena se re lumella ho etsa bonnete ba hore sehlahisoa sa ho qetela se kopana le litlhoko tsa hau ka mokhoa o phethahetseng.

Hajoale, sehlopha sa rona se sebetsa ka ho khetheha litšebeletsong tsa setempe sa tšepe tse ikhethileng libakeng tse latelang:

Setempe se tsoelang pele bakeng sa lihlopha tse nyenyane le tse kholo

Sehlopha se senyenyane sa setempe sa bobeli

Ho tlanya ka har'a hlobo

Ho tlanya ha bobeli/kopanong

Ho theha le ho etsa mechine

Re tla ikitlaelletsa ho fa bareki ba rona ba hlomphuoang re sebelisa lits'ebeletso tse nahannoeng ka tjantjello bakeng sa Basebetsi ba Kaho ea Liphoofolo tse kholo tsa Kaho ea Elevator le Li-Wire Rope Connectors, Hammoho le boikitlaetso ba rona, lihlahisoa tsa rona le tharollo li hapile ts'epo ea bareki mme li ka rekisoa haholo mona le kantle ho naha.

Theko e kholoLisebelisoa tsa Kaho ea Chaena le Lisebelisoa tsa Kaho, Moralo, ts'ebetso, ho reka, ho hlahloba, ho boloka, ho bokella, kaofela li ts'ebetsong ea mahlale le e sebetsang ea litokomane, ho eketsa boemo ba ts'ebeliso le ts'epahalo ea mofuta oa rona ka botebo, e leng se etsang hore re be morekisi ea phahameng oa lihlopha tse 'ne tse kholo tsa lihlahisoa tsa likhetla ka har'a naha mme re fumane ts'epo ea moreki hantle.